Water-Cooled IE31A 408L Programmable Thermal Shock Chamber Environment Test Equipment

IE31A408L Programmable Thermal Shock Chamber Environment Test EquipmentGerman Bitzer Semi-Dense Type Compressor

Programmable thermal shock test chamber.pdf

Which Refrigeration Compressors does this machine used?

We use high quality German Bitzer semi-dense type compressor.

What is the Condenser method for this machine ?

It is Water-cooled.

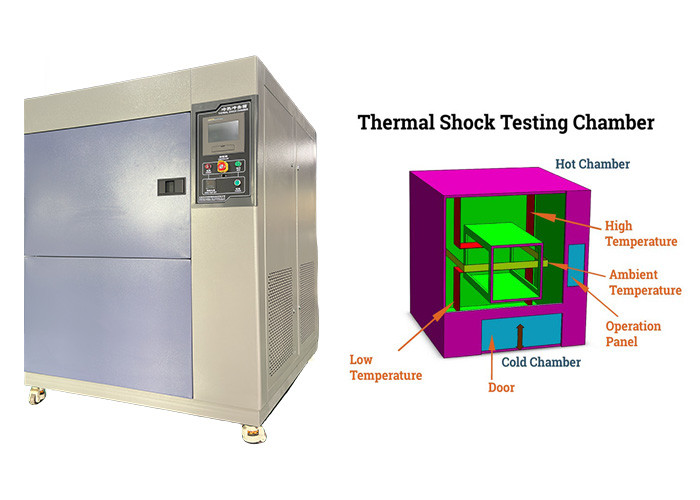

Equipment Overview:

Programmable Thermal Shock Chamber is used for users to conduct corresponding climate mutation tests on complete products (or components), electrical appliances, instruments, materials, coatings, plating, etc.

It is suitable for high and low temperature testing on electrical, electronic, mechanical industries and other products, components, materials, etc. ,

Humidity and heat test: conduct hot and cold shock test under simulated temperature and humidity changes to evaluate the quality of the test product.

Applicable standards:

l GB/T2423.1-2001Low temperature test method;

l GB/T2423.2-2001;

l GB/T2423.22-1989Temperature change test;

l National Military StandardGJB150.3-86;

l National Military StandardGJB150.4-86;

l National Military StandardGJB150.5-86;

l GJB150.5-86Temperature shock test

l GJB360.7-87Temperature shock test;

l GJB367.2-87 405Temperature shock test;

l J/T10187-91Y73 Temperature change test chamber—three-box type;

l Meets the standard IEC68-2-14_Test method N_Temperature change.

Specificities:

l Energy saving and consumption reduction: Use gas-liquid bypass mode to adjust the cooling capacity to achieve constant temperature and humidity.

l Easy to operate: Programmable color LCD touch controller can be combined with PID control; experimental data recording and processing methods are flexible.

l High reliability: all key components are imported to ensure service life and reliability.

Specification:

| Model |

IE31A80L |

IE31A100L |

IE31A150L |

IE31A225L |

IE31A408L |

| Temperature range |

-55℃ ~ +150℃ |

| Temperature fluctuation |

±1℃ |

| Temperature uniformity |

≦2.0℃ |

| Temperature recovery time |

Within 5Minc |

| Heating rate (heat storage area) |

It takes about 40 minutes to rise from RT to +150℃ |

It takes about 50 minutes to rise from RT to +150℃ |

| Cooling rate (cold storage area) |

It takes about 65 minutes to drop from RT to -55℃ |

It takes about 70 minutes to drop from RT to -55℃ |

|

Inner box size:

WxHxD(mm)

|

500x400x400 |

500x400x500 |

500x600x500 |

500x750x600 |

600×850×800 |

|

Carton size:

WxHxD(mm)

|

1480×1450 ×1950 |

1480×1485×2050 |

1500×1750×2150 |

1600×1900×2250 |

1800x2000x2500 |

| Insulation box |

● Outer wall material: high-quality carbon steel plate, surface treated with electrostatic color spraying. The left side of the box has a diameter of φ50mm.

● Inner wall material: SUS304# matte stainless steel plate.

● Insulation material: rigid polyurethane foam insulation layer + glass fiber.

|

| Chamber door |

For single-door doors, install a door frame heating wire at the door frame to prevent condensation on the door frame at low temperatures. |

| Observation window |

Install a W 300×H 400mm observation window on the door. The multi-layer hollow electrothermal coated glass can effectively preserve heat and prevent condensation. |

| sample holder |

Stainless steel sample rack with 2 layers, adjustable layer height, load capacity 30kg/layer. |

| Refrigeration Compressors |

French Taikang fully enclosed compressor

|

German Bitzer semi-closed compressor

|

German Bitzer semi-closed compressor

|

German Bitzer semi-closed compressor

|

German Bitzer semi-dense type

compressor

|

| Refrigerant |

Non-fluorine environmentally friendly refrigerant

R404A R23 complies with environmental regulations, safe and non-toxic

|

| Condenser method |

Air-cooled |

Water-cooled |

Water-cooled |

Water-cooled |

Water-cooled |

| Safety protection device |

Heater anti-air fire protection; heater over-current protection; circulation fan over-current and overload protection; compressor high-voltage protection; compressor over-heat protection; compressor over-current protection; over-voltage reverse phase protection; line circuit breaker; leakage protection. |

| Power supply |

AC380V;50Hz;18KW |

AC380;V50Hz;18KW |

AC380;V50Hz;22KW |

AC380;V50Hz;22KW |

AC380;V50Hz;25KW |

FAQ:

- Q: What is the brand name of the Thermal Shock Chamber?

A: The brand name of the Environmental Test Chamber is Infinity Machine.

- Q: What is the model number of the Thermal Shock Chamber?

A: The model number of the Environmental Test Chamber is IE31A408L.

- Q: Where is the Thermal Shock Chamber made?

A: The Environmental Test Chamber is made in China.

- Q: Does the Thermal Shock Chamber have any certifications?

A: Yes, the Environmental Test Chamber has CE and ISO certifications.

- Q: How long is the delivery time for the Thermal Shock Chamber?

A: The delivery time for the Environmental Test Chamber is 200sets per monthes.

- Q: What payment terms are accepted for the Thermal Shock Chamber?

A: The payment terms accepted for the Environmental Test Chamber are T/T, D/P, and L/C.

Contact us

Mobile/Whatsapp:+86-189-2293-3631

Tel:+86-(0)76987796906

https://www.tester-machine.com/

Infinity Machine International Inc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!