Product Description:

One of the key features of this Thermal Shock Test Chamber is its cooling rate from the cold storage area. It can go down from RT to -55℃ in about 75 minutes, providing a rapid cooling environment for your products. This feature is essential in simulating extreme weather conditions, which is crucial in testing the resilience of your products.

The refrigeration compressor of this Thermal Shock Test Chamber is a half-compact compressor from Bitzer, Germany. This compressor is known for its durability and efficiency, ensuring that your products are tested in an environment with consistent and precise temperature control.

Temperature recovery time is also a critical feature of this Thermal Shock Test Chamber. It only takes within five minutes for the temperature to recover, ensuring that the testing process is not interrupted and that accurate results are obtained.

The Thermal Shock Test Chamber's source is AC380V; 50Hz; 18KW, providing the necessary power for a reliable testing environment. This feature ensures that your products undergo testing with consistent and accurate temperature control.

The heating rate from the heat storage area is another essential feature of this product. It can go up from RT to +150℃ in about 50 minutes, providing a rapid heating environment for your products. This feature is necessary in simulating extreme weather conditions, which is crucial in testing the resilience of your products.

Overall, the Thermal Shock Test Chamber is a must-have for any industry that requires testing of products in extreme temperature conditions. With its innovative features, such as rapid cooling and heating rates, temperature recovery time, and reliable power source, it ensures accurate and efficient testing of your products.

Features:

- Product Name: Thermal Shock Test Chamber

- Standards:

- GB/T2423.1-2001 Low Temperature Test Method

- GB/T2423.2-2001

- GB/T2423.22-1989 Temperature Change Test

- Standard GJB150.3-86

- Standard GJB150.4-86

- Standard GJB150.5-86

- GJB150.5-86 Temperature Impact Test

- GJB360.7-87 Temperature Shock Test

- GJB367. 2-87 405 Temperature Shock Test

- J/T10187-91Y73 Series Temperature Change Test Box-three-box Type

- Meet The Standard IEC68-2-14_ Test Method _ Temperature Change

- Features:

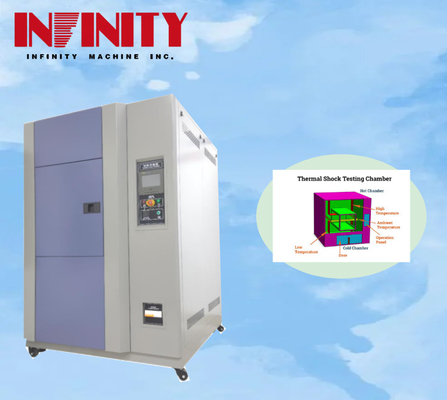

- Energy Saving And Consumption Reduction: Use Gas-liquid Bypass Mode To Adjust The Cooling Capacity To Achieve Constant Temperature And Humidity

- Simple Operation: Programmed Color LCD Touch Controller Reference Group PID Control; Experimental Data Recording And Processing Mode Is Flexible

- High Reliability: The Key Parts Are Imported Parts To Ensure The Service Life And Reliability

- Observation window: W300 *H400mm Observation Window Is Installed On The Box Door. Multi-layer Insulating Electric Thermal Coated Glass Can Effectively Provide Heat Preservation And Prevent Condensation

- Safety protection device: Heater Air Defense Incineration Protection; Heater Over Current Protection; Circulation Fan Over Current Overload Protection; Compressor High Pressure Protection;. Compressor Overheat Protection; Compressor Over Current Protection; Over Voltage Under Reverse Phase Protection; Circuit Breaker; Leakage Protection

- Model number: IE31A1 Series

Technical Parameters:

| Product Name |

Programmable Cold and Hot Shock Test Chamber |

| Temperature Range |

-65℃ ~ +150℃ |

| Observation Window |

W300 *H400mm observation window is installed on the box door. Multi-layer insulating electric thermal coated glass can effectively provide heat preservation and prevent condensation. |

| Specimen Holder |

Stainless steel sample frame 2 layers, adjustable height, bearing weight of 30kg/layer. |

| Safety Protection Device |

Heater air defense incineration protection; heater over current protection; circulation fan over current overload protection; compressor high pressure protection; compressor overheat protection; compressor over current protection; over voltage under reverse phase protection; circuit breaker; leakage protection. |

| Condenser Mode |

Water-cooled |

| Temperature Recovery Time |

Within 5 minutes |

| Temperature Uniformity |

≦2.0℃ |

| Equipment Overview |

For users to the whole machine (or parts), electrical appliances, instruments, materials, coating, coating for the corresponding climate mutation test, suitable for electrical, electronics, machinery industry and other products, parts, materials, such as high and low temperature, humidity test, simulate the temperature and humidity changes under the condition of cold and cold impact test, so as to evaluate the quality of the test products. |

| Heating Rate (Heat Storage Area) |

Up from RT to +150℃ about 50 minutes is required (or specify). |

Applications:

The INFINITY IE31A1 Series Thermal Shock Test Chamber is a high-quality testing equipment that is made in China and certified with CE and ISO. It is designed to test the ability of products to withstand extreme temperature changes and sudden thermal shocks.

With a minimum order quantity of 1 and negotiable pricing, the Thermal Shock Test Chamber is the perfect choice for laboratories, research facilities, and manufacturing plants. The packaging details include clear sheet+sponge+wood carton, and the delivery time is 20-30 days after order confirmation. Payment terms are flexible, including TT, PayPal, Moneygram, and more. The supply ability is 200 sets per month, ensuring that the product is readily available for customers.

The Thermal Shock Test Chamber comes with an observation window of W300*H400mm, installed on the box door. Multi-layer insulating electric thermal coated glass provides heat preservation and prevents condensation, ensuring clear observation during testing.

The Thermal Shock Test Chamber complies with various standards, including GB/T2423.1-2001 Low Temperature Test Method, GB/T2423.2-2001, GB/T2423.22-1989 Temperature Change Test, Standard GJB150.3-86, Standard GJB150.4-86, Standard GJB150.5-86, GJB150.5-86 Temperature Impact Test, GJB360.7-87 Temperature Shock Test, GJB367.2-87 405 Temperature Shock Test, and J/T10187-91Y73 Series Temperature Change Test Box-three-box Type. It also meets the standard IEC68-2-14_ Test Method _ Temperature Change.

The Thermal Shock Test Chamber has several features, including energy-saving and consumption reduction capabilities through a gas-liquid bypass mode that adjusts cooling capacity for constant temperature and humidity. It has a programmed color LCD touch controller with reference group PID control, and the experimental data recording and processing mode is flexible. The key parts are imported parts, ensuring high reliability, service life, and reliability.

The Thermal Shock Test Chamber has a temperature range of -65℃ ~ +150℃, and the source is AC380V;50Hz;18KW (or specify). It is also known as a Thermal Shock Test Chamber, Thermal Shock Test Chamber, or Temperature Rapid Change Tester. Choose the INFINITY IE31A1 Series Thermal Shock Test Chamber for accurate and reliable testing of product durability and performance under extreme temperature changes and sudden thermal shocks.

Customization:

The cooling rate in the cold storage area is down from RT to -55℃ and takes about 75 minutes (or specify). The temperature uniformity is ≦2.0℃. The source is AC380V;50Hz;18KW (or specify). The model number is IE31A1 Series. The product name is Programmable Cold and Hot Shock Test Chamber.

Support and Services:

- Installation and commissioning services to ensure proper setup and operation of the chamber

- On-site training for operators and maintenance personnel to ensure proper use and maintenance of the equipment

- Remote technical support to address any issues or questions that may arise during operation

- Preventative maintenance programs to help extend the life of the chamber and minimize downtime

- Calibration and validation services to ensure accurate and reliable test results

- Repair and replacement services to address any equipment failures or malfunctions

Our team of experienced technical support and service professionals are dedicated to providing timely and effective solutions to any issues or questions you may have. Contact us to learn more about our Thermal Shock Test Chamber support and services.

Packing and Shipping:

Product Packaging:

- The Thermal Shock Test Chamber will be packaged securely in a wooden crate to ensure safe transportation.

- The crate will be marked with clear labels indicating the product name and any necessary handling instructions.

Product Shipping:

- The Thermal Shock Test Chamber will be shipped via a reliable and trusted freight carrier.

- The shipping cost will be calculated based on the destination and weight of the product.

- A tracking number will be provided to the customer for easy monitoring of the shipment status.

FAQ:

Q: What is the brand name of the Thermal Shock Test Chamber?

A: The brand name of the Thermal Shock Test Chamber is INFINITY.

Q: What is the model number of the Thermal Shock Test Chamber?

A: The model number of the Thermal Shock Test Chamber is IE31A1 Series.

Q: Where is the Thermal Shock Test Chamber made?

A: The Thermal Shock Test Chamber is made in China.

Q: What certifications does the Thermal Shock Test Chamber have?

A: The Thermal Shock Test Chamber is certified with CE and ISO.

Q: What is the minimum order quantity for the Thermal Shock Test Chamber?

A: The minimum order quantity for the Thermal Shock Test Chamber is 1.

Q: What is the packaging details of the Thermal Shock Test Chamber?

A: The packaging details of the Thermal Shock Test Chamber include clear sheet+sponge+wood carton.

Q: What is the delivery time for the Thermal Shock Test Chamber?

A: The delivery time for the Thermal Shock Test Chamber is 20-30 days after order confirmed.

Q: What are the payment terms for the Thermal Shock Test Chamber?

A: The payment terms for the Thermal Shock Test Chamber include TT, PAYPAL, Moneygram, and so on.

Q: What is the supply ability of the Thermal Shock Test Chamber?

A: The supply ability of the Thermal Shock Test Chamber is 200 sets per month.

Q: Is the price of the Thermal Shock Test Chamber negotiable?

A: Yes, the price of the Thermal Shock Test Chamber is negotiable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!