Product Description:

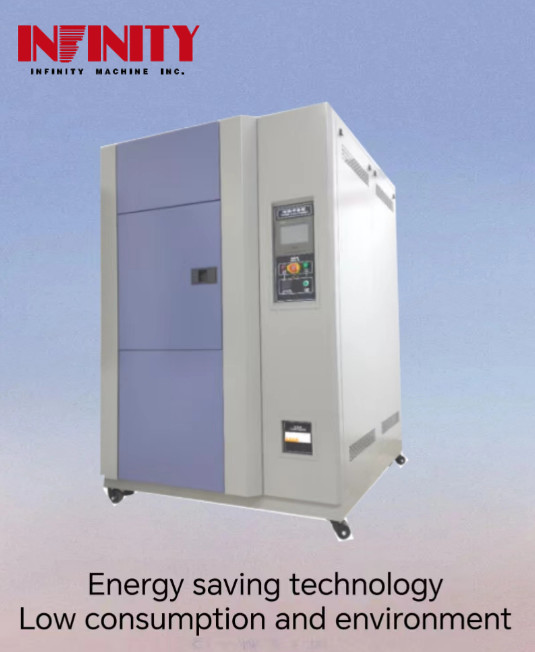

The Thermal Shock Environment Test Equipment, also known as the Thermal Shock Test Chamber or Hot and Cold Impact Test Chamber, is a cutting-edge testing device designed to simulate extreme temperature changes for various products. This chamber is equipped with advanced features to provide accurate and reliable results, making it an essential tool for industries such as electronics, automotive, aerospace, and more.

One of the key attributes of this product is its rapid temperature recovery time, which is within 5 minutes. This quick recovery time ensures efficient testing processes and reduces downtime, allowing for faster and more productive testing cycles.

The Thermal Shock Test Chamber uses non-fluorine environmental protection refrigerants R404A and R23, complying with environmental protection regulations. These refrigerants are safe and non-toxic, making them ideal for testing sensitive components without causing harm to the environment or operators.

With an internal box size of WxHxD(mm): 500x400x400 (or specify), this chamber provides ample space for testing various sized products. The spacious interior allows for flexibility in testing different types of products, making it a versatile solution for a wide range of testing requirements.

Designed with a water-cooled condenser mode, the Thermal Shock Test Chamber ensures efficient cooling performance during testing cycles. The water-cooled condenser helps maintain stable temperature conditions within the chamber, providing consistent and accurate test results.

Overall, the Thermal Shock Environment Test Equipment is a reliable and advanced testing solution for conducting hot and cold impact tests. Its rapid temperature change capabilities, environmentally friendly refrigerants, spacious interior, and efficient cooling system make it an ideal choice for industries looking to ensure the quality and reliability of their products.

Features:

- Product Name: Thermal Shock Test Chamber

- Refrigeration compressor: Half-compact Compressor In Bitzer, Germany

- Equipment overview: For Users To The Whole Machine (or Parts), Electrical Appliances, Instruments, Materials, Coating, Coating For The Corresponding Climate Mutation Test, Suitable For Electrical, Electronics, Machinery Industry And Other Products, Parts, Materials, Such As High And Low Temperature, Humidity Test, Simulate The Temperature And Humidity Changes Under The Condition Of Cold And Cold Impact Test, So As To Evaluate The Quality Of The Test Products.

- Features:

- Energy Saving And Consumption Reduction: Use Gas-liquid Bypass Mode To Adjust The Cooling Capacity To Achieve Constant Temperature And Humidity.

- Simple Operation: Programmed Color LCD Touch Controller Reference Group PID Control; Experimental Data Recording And Processing Mode Is Flexible.

- High Reliability: The Key Parts Are Imported Parts To Ensure The Service Life And Reliability.

- Thermal insulation box:

- Outer Wall Material: High Quality Carbon Steel Plate, The Surface For Electrostatic Color Spray Plastic Treatment. The Left Side Diameter Of The Box Is φ 50mm Hole.

- Inner Wall Material: SUS304 # Fog Surface Stainless Steel Plate.

- Thermal Insulation Material: Hard Polyurethane Foam Thermal Insulation Layer + Glass Fiber.

- Source: AC380V;50Hz;18KW(or Specify)

Technical Parameters:

| Temperature recovery time |

Within 5 Min |

| Features |

Energy Saving And Consumption Reduction: Use Gas-liquid Bypass Mode To Adjust The Cooling Capacity To Achieve Constant Temperature And Humidity. Simple Operation: Programmed Color LCD Touch Controller Reference Group PID Control; Experimental Data Recording And Processing Mode Is Flexible. High Reliability: The Key Parts Are Imported Parts To Ensure The Service Life And Reliability. |

| Condenser mode |

Water-cooled |

| Internal box size: WxHxD(mm) |

500x400x400(or Specify) |

| Observation window |

W300 *H400mm Observation Window Is Installed On The Box Door. Multi-layer Insulating Electric Thermal Coated Glass Can Effectively Provide Heat Preservation And Prevent Condensation. |

| Source |

AC380V;50Hz;18KW(or Specify) |

| Specimen holder |

Stainless Steel Sample Frame 2 Layers, Adjustable Height, Bearing Weight Of 30kg / Layer. |

| Temperature fluctuation |

±1℃ |

| Thermal insulation box |

● Outer Wall Material: High Quality Carbon Steel Plate, The Surface For Electrostatic Color Spray Plastic Treatment. The Left Side Diameter Of The Box Is φ 50mm Hole. ● Inner Wall Material: SUS304 # Fog Surface Stainless Steel Plate. ● Thermal Insulation Material: Hard Polyurethane Foam Thermal Insulation Layer + Glass Fiber. |

| Product name |

Thermal Shock Environment Test Equipment, Thermal Shock Test Chamber, Hot and Cold Impact Test Chamber, Rapid Temperature Change Thermal Shock Test Chamber, Rapid Ambient Temperature Change Test Machine, Rapid Temperature Changes Test Chamber, Rapid Temperature Change Testing Machine, Rapid Temperature Climate Test Chamber, Rapid Temperature Climate Testing Chamber, Rapid Temperature Change Environment Testing Machine, Rapid Temperature Change Environment Test Chamber |

Applications:

The Thermal Shock Test Chamber, also known as a Hot and Cold Impact Test Chamber, from the INFINITY brand (Model Number: IE31A1 Series) is a versatile and reliable product designed for a variety of testing applications. Made in China, this chamber is ISO certified, ensuring high quality and performance standards.

With a minimum order quantity of 1 and negotiable pricing, the Thermal Shock Test Chamber is suitable for a wide range of industries and businesses. It comes with standard export wooden carton packaging and has a delivery time of 35-50 days after order confirmation. Payment terms are by Telegraphic Transfer, making the purchasing process convenient for customers.

The chamber boasts a supply ability of 200 sets per month, making it readily available for large-scale testing needs. It features a half-compact compressor from Bitzer, Germany, ensuring efficient and reliable refrigeration performance.

Operating within a temperature range of -65℃ to +150℃, this chamber uses non-fluorine environmental protection refrigerants R404A and R23, complying with environmental regulations while remaining safe and non-toxic.

An observation window sized at W300 * H400mm is installed on the box door, allowing for easy monitoring of tests. The multi-layer insulating electric thermal coated glass provides effective heat preservation and prevents condensation during testing procedures.

The Thermal Shock Test Chamber offers a rapid heating rate, taking approximately 50 minutes to reach from room temperature to +150℃ in the heat storage area, ensuring efficient and precise testing processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!