Product Description:

The Product Name: Programmed Cold And Hot Impact Test Chamber is designed to meet various testing standards such as GB/T2423.1-2001 Low Temperature Test Method, GB/T2423.2-2001, GB/T2423.22-1989 Temperature Change Test, Military Standard GJB150.3-86, Military Standard GJB150.4-86, Military Standard GJB150.5-86, GJB150.5-86 Temperature Impact Test, GJB360.7-87 Temperature Shock Test, GJB367. 2-87 405 Temperature Shock Test, J / T10187-91Y73 Series Temperature Change Test Box-three Box Type, and meets the standard IEC68-2-14_ test method N_ Temperature Change.

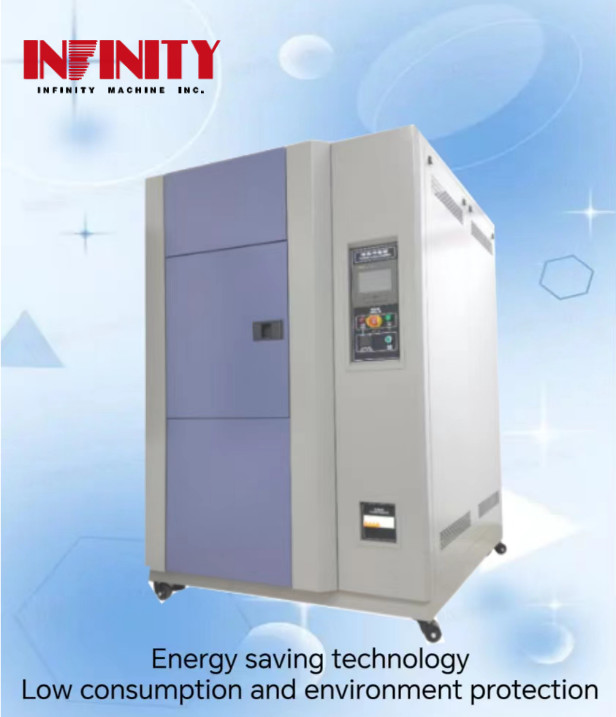

The Thermal Shock Test Chamber's condenser mode is air-cooled, offering a reliable and efficient cooling solution. The temperature uniformity of this Programmable Hot Cold Shock Test Chamber is ≦2.0℃, which is ideal for testing products that require precise temperature control and uniformity during testing. The test chamber's specimen holder is made of stainless steel and has 2 layers that can be adjusted in height, with each layer bearing a weight of 30kg.

The Programmable Hot Cold Shock Test Chamber is easy to use and comes with a user-friendly interface that allows operators to program and control the test conditions easily. This test chamber is equipped with a high-precision temperature control system that ensures accurate and stable temperature control during testing. The test chamber's fast temperature change rate and excellent temperature recovery time make it a reliable and efficient testing tool.

In conclusion, the Thermal Shock Test Chamber or Programmable Hot Cold Shock Test Chamber is an essential testing tool for manufacturers of electronic devices, automotive parts, aerospace components, and other products that need to withstand sudden temperature changes. With its air-cooled condenser mode, precise temperature control, and easy-to-use interface, this test chamber is an ideal testing tool for any laboratory that requires reliable and efficient thermal shock testing.

Features:

- Product Name: Thermal Shock Test Chamber

- Refrigeration compressor: France Tecumseh Fully Closed Compressor

- Standards:

- GB/T2423.1-2001 Low Temperature Test Method

- GB/T2423.2-2001

- GB/T2423.22-1989 Temperature Change Test

- Military Standard GJB150.3-86

- Military Standard GJB150.4-86

- Military Standard GJB150.5-86

- GJB150.5-86 Temperature Impact Test

- GJB360.7-87 Temperature Shock Test

- GJB367.2-87 405 Temperature Shock Test

- J/T10187-91Y73 Series Temperature Change Test Box-three Box Type

- Meet The Standard IEC68-2-14_ Test Method N_ Temperature Change

- Chamber door: Open The Door Alone, Add The Door Frame Heating Wire At The Door Frame To Prevent Condensation At The Door Frame At Low Temperature.

- Temperature recovery time: Within 5 Mint

- Thermal insulation chamber:

- Outer Wall Material: High Quality Carbon Steel Plate, The Surface For Electrostatic Color Spray Plastic Treatment. The Left Side Diameter Of The Box Is φ 50mm Hole

- Inner Wall Material: SUS304 # Fog Surface Stainless Steel Plate

- Thermal Insulation Material: Hard Polyurethane Foam Thermal Insulation Layer + Glass Fiber

Technical Parameters:

| Product name: |

Programmed Cold And Hot Impact Test Chamber |

| Temperature range: |

-40℃ ~ +150℃ |

| Internal box size: |

WxHxD(mm): 500x400x400(or Specify) |

| Standards: |

GB/T2423.1-2001 Low Temperature Test Method; GB/T2423.2-2001; GB/T2423.22-1989 Temperature Change Test; Military Standard GJB150.3-86; Military Standard GJB150.4-86; Military Standard GJB150.5-86; GJB150.5-86 Temperature Impact Test; GJB360.7-87 Temperature Shock Test; GJB367. 2-87 405 Temperature Shock Test; J / T10187-91Y73 Series Temperature Change Test Box-three Box Type; Meet The Standard IEC68-2-14_ Test Method N_ Temperature Change. |

| Thermal insulation chamber: |

● Outer Wall Material: High Quality Carbon Steel Plate, The Surface For Electrostatic Color Spray Plastic Treatment. The Left Side Diameter Of The Box Is φ 50mm Hole ● Inner Wall Material: SUS304 # Fog Surface Stainless Steel Plate. ● Thermal Insulation Material: Hard Polyurethane Foam Thermal Insulation Layer + Glass Fiber. |

| Observation window: |

W300 *H400mm Observation Window Is Installed On The Box Door. Multi-layer Insulating Electric Thermal Coated Glass Can Effectively Provide Heat Preservation And Prevent Condensation. |

| Cooling rate (cold storage area): |

Down From RT To-40℃ About 55min Is Required(or Specify) |

| Temperature uniformity: |

≦2.0℃ |

| Temperature recovery time: |

Within 5 Mint |

| Features: |

Energy Saving And Consumption Reduction: Use Gas-liquid Bypass Mode To Adjust The Cooling Capacity To Achieve Constant Temperature And Humidity. Simple Operation: Programmed Color LCD Touch Controller Reference Group PID Control; Experimental Data Recording And Processing Mode Is Flexible. High Reliability: The Key Parts Are Imported Parts To Ensure The Service Life And Reliability. |

Applications:

The INFINITY IE31 Series Programmable Hot Cold Shock Test Chamber is a high-quality thermal shock test chamber that is made in China and comes with CE and ISO certification. This product is an ideal choice for companies that need to test the performance of their products under extreme temperature changes. The minimum order quantity for this product is 1, and the price can be negotiated based on the order quantity.

The product comes with clear sheet+sponge+wood carton packaging to ensure that it is delivered to the customers in perfect condition. The delivery time for this product is around 20-30 days after the order is confirmed, and the payment terms include TT, PAYPAL, Moneygram, and other options. The supply ability of this product is 200 sets per month.

The Thermal Shock Test Chamber comes with non-fluorine environmental protection refrigerant R404A R23, which complies with environmental protection regulations and is safe and non-toxic. The internal box size is WxHxD(mm): 500x400x400(or Specify), and the thermal insulation chamber is made of high-quality carbon steel plate with the surface for electrostatic color spray plastic treatment. The left side diameter of the box is φ 50mm hole. The inner wall material is SUS304 # fog surface stainless steel plate, and the thermal insulation material is hard polyurethane foam thermal insulation layer + glass fiber.

The source for this product is AC380V;50Hz;18KW(or Specify), and the product features energy-saving and consumption reduction. The gas-liquid bypass mode is used to adjust the cooling capacity to achieve constant temperature and humidity. The product is simple to operate, with a programmed color LCD touch controller reference group PID control and a flexible experimental data recording and processing mode. The key parts of this product are imported to ensure the service life and reliability of the product.

The Thermal Shock Test Chamber is an ideal product for companies that need to test the performance of their products under extreme temperature changes. The product application occasions and scenarios include testing electronic components, PCBs, automotive parts, rubber, plastic, and other materials' performance under extreme temperature changes. The product is also suitable for testing the thermal shock resistance of aerospace equipment, military equipment, and other high-tech products. With its high reliability and ease of use, the Thermal Shock Test Chamber is a must-have product for companies that want to ensure the quality of their products.

Customization:

Brand Name: INFINITY

Model Number: IE31 Series

Place of Origin: MADE IN CHINA

Certification: CE ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT PAYPAL Moneygram and so on

Supply Ability: 200 sets / month

Features: Energy Saving And Consumption Reduction: Use Gas-liquid Bypass Mode To Adjust The Cooling Capacity To Achieve Constant Temperature And Humidity. Simple Operation: Programmed Color LCD Touch Controller Reference Group PID Control; Experimental Data Recording And Processing Mode Is Flexible. High Reliability: The Key Parts Are Imported Parts To Ensure The Service Life And Reliability.

Equipment overview: For Users To The Whole Machine (or Parts), Electrical Appliances, Instruments, Materials, Coating, Coating For The Corresponding Climate Mutation Test, Suitable For Electrical, Electronics, Machinery Industry And Other Products, Parts, Materials, Such As High And Low Temperature, Humidity Test, Simulate The Temperature And Humidity Changes Under The Condition Of Cold And Cold Impact Test, So As To Evaluate The Quality Of The Test Products.

Thermal Shock Test Chamber Internal box size: WxHxD(mm): 500x400x400 (or Specify)

Chamber door: Open The Door Alone, Add The Door Frame Heating Wire At The Door Frame To Prevent Condensation At The Door Frame At Low Temperature.

Temperature uniformity: ≦2.0℃

Support and Services:

Our technical support team is available to assist with installation, calibration, and maintenance of your Thermal Shock Test Chamber. We also provide training to help operators get the most out of their equipment and ensure safe and efficient operation.

In addition, we offer a range of services to help customers troubleshoot issues and quickly resolve any problems that may arise. Our team of experts can provide remote support, on-site repair services, and replacement parts to ensure minimal downtime and maximum productivity.

With our commitment to quality and customer satisfaction, you can trust us to provide the support and services you need to get the most out of your Thermal Shock Test Chamber.

Packing and Shipping:

Product Packaging:

The Thermal Shock Test Chamber will be securely packed in a wooden crate to ensure safe transportation. The crate will be lined with foam and the product will be securely fastened in place to prevent any movement during transport.

Shipping:

The Thermal Shock Test Chamber will be shipped via a reputable courier service. The shipping cost will be calculated based on the destination and weight of the product. The customer will be provided with a tracking number to monitor the shipment's progress.

FAQ:

Q: What is the brand name of this thermal shock test chamber?

A: The brand name is INFINITY.

Q: What is the model number of this thermal shock test chamber?

A: The model number is IE31 Series.

Q: Where is the thermal shock test chamber made?

A: It is made in China.

Q: What certifications does this thermal shock test chamber have?

A: It has CE and ISO certifications.

Q: What is the minimum order quantity for this thermal shock test chamber?

A: The minimum order quantity is 1.

Q: What is the price of this thermal shock test chamber?

A: The price is negotiable.

Q: What are the packaging details for this thermal shock test chamber?

A: The packaging details include a clear sheet, sponge, and wood carton.

Q: What is the delivery time for this thermal shock test chamber?

A: The delivery time is 20-30 days after order confirmed.

Q: What are the payment terms for this thermal shock test chamber?

A: The payment terms include TT, PayPal, Moneygram, and so on.

Q: What is the supply ability of this thermal shock test chamber?

A: The supply ability is 200 sets per month.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!