Product Description:

Product Overview

The Thermal Shock Test Chamber is a highly efficient and advanced testing equipment designed for conducting thermal shock tests on various products, components, electrical appliances, instruments, materials, coatings, and more. This chamber is suitable for industries such as electrical, electronic, mechanical, and others, and is capable of evaluating the quality and performance of products under extreme temperature and humidity conditions.

With a Temperature Recovery Time of ≤5 minutes, this Programmable Thermal Shock Chamber offers fast and accurate temperature recovery, ensuring efficient testing and evaluation of products. The chamber is equipped with an Inner Material made of SUS304# Stainless Steel Plate, providing excellent durability and corrosion resistance.

The Temperature Fluctuation of ±1℃ ensures precise and consistent testing results, making it suitable for a wide range of applications. The chamber also comes with a Condenser System, with IE31 80L-100L models being Air-cooled and IE31 150L-408L models being Water-cooled, providing flexibility and versatility in testing various products.

Key Features:

- Programmable Thermal Shock Chamber

- Programmable Hot Cold Shock Test Chamber

- Programmable Cryogenic Thermal Shock Chamber

- Temperature Recovery Time: ≤5 Minutes

- Inner Material: SUS304# Stainless Steel Plate

- Temperature Fluctuation: ±1℃

- Condenser System: Air-cooled or Water-cooled

Applications:

The Thermal Shock Test Chamber is suitable for testing a wide range of products, components, materials, and coatings, including but not limited to:

- Electrical appliances

- Electronic components

- Mechanical parts

- Materials

- Coatings

- And more

Testing Capabilities:

The chamber is capable of conducting various tests, including:

- High and low-temperature testing

- Thermal testing

- Wet testing

- Thermal shock testing

- Temperature and humidity testing

With its advanced features and capabilities, the Thermal Shock Test Chamber is an essential tool for any industry that requires precise and reliable testing of products under extreme environmental conditions.

| Model |

IE 3180L |

IE 31100L |

IE 31150L |

IE 31225L |

IE 31408L |

| Temperature range |

-40℃ ~ +150℃ |

| Temperature fluctuation |

±1℃ |

| Temperature uniformity |

≦2.0℃ |

| Temperature recovery time |

Within 5M in c |

| Heating rate (heat storage area) |

Up from RT to + 150℃ About 35m in is required |

Up from RT to + 150℃ About 40m in is required |

| Cooling rate (cold storage area) |

Down from RT to-40℃ Approximately 55min is required |

Down from RT to-40℃ Approximately 60min is required |

|

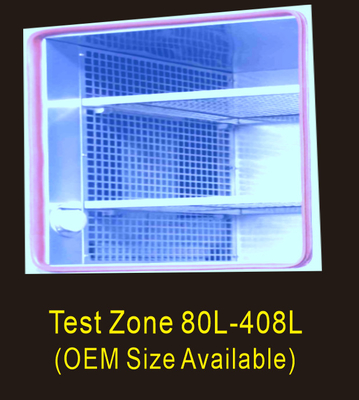

Internal chamber size:

WxHxD(mm )

|

500x 400x400 |

500x 400x500 |

500x 600x500 |

500x750x600 |

600×850×800 |

|

Out chamber size:

WxHxD(mm )

|

1480×1450 ×1950 |

1480×1485×2050 |

1500×1750×2150 |

1600×1900×2250 |

1800x2000x2500 |

| Thermal insulation box |

● Outer wall material: high quality carbon steel plate, the surface for electrostatic color spray plastic treatment. The left side diameter of the box is φ 50mm hole

● Inner wall material: SUS304 # fog surface stainless steel plate.

● Thermal insulation material: hard polyurethane foam thermal insulation layer + glass fiber.

|

| Chamber door |

Open the door alone, add the door frame heating wire at the door frame to prevent condensation at the door frame at low temperature. |

| Observation window |

A W 300 H 400mm observation window is installed on the box door. Multi-layer insulating electric thermal coated glass can effectively provide heat preservation and prevent condensation. |

| Specimen holder |

Stainless steel sample frame 2 layers, adjustable height, bearing weight of 30kg / layer. |

| Refrigeration compressor |

France taikang fully closed compressor |

France taikang fully closed compressor |

Half-compact compressor in Bizel, Germany |

Half-compact compressor in Bizel, Germany |

Half-compact compressor in Bizel, Germany |

| Cooling medium |

Non-fluorine environmental protection refrigerant R404A R23 comply with environmental protection regulations, safe and non-toxic |

| Condenser mode |

air-cooled |

air-cooled |

water-cooled |

water-cooled |

water-cooled |

| Safety protection device |

Heater air defense incineration protection; heater over current protection; circulation fan overcurrent overload protection; compressor high pressure protection;. Compressor overheat protection; compressor overcurrent protection; overvoltage underreverse phase protection; circuit breaker; leakage protection. |

| Power |

AC380V;50Hz;18KW |

AC 380;V50Hz;18KW |

AC 380;V50Hz;22KW |

AC 380;V50Hz;22KW |

AC 380;V50Hz;25KW |

Applications:

INFINITY IE31 Series Thermal Shock Test Chamber

Product Description:

The INFINITY IE31 Series Thermal Shock Test Chamber is a highly reliable and efficient testing equipment designed for conducting thermal shock tests on various materials and products. It is widely used in industries such as electronics, aerospace, automotive, and defense for testing the ability of products to withstand sudden temperature changes.

Brand Name: INFINITY

Model Number: IE31 Series

Place of Origin: MADE IN CHINA

Certification: CE ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT PAYPAL Moneygram and so on

Supply Ability: 200 sets/month

Product Features:

- Programmable High-Low Temperature Shock Test Chamber

- Programmable Thermal Cycling Shock Test Chamber

- Programmable Alternating Thermal Shock Chamber

- Temperature uniformity of ≦2.0℃

- Heating rate of 80L - 100L: It takes about 35 minutes for the room temperature to drop to -55℃; 150L - 408L: It takes about 40 minutes for the room temperature to drop to -55℃

- Temperature fluctuation of ±1℃

- Chamber volume size ranging from 80L to 408L

- Temperature recovery time of ≤5 minutes

Application Scenarios:

The INFINITY IE31 Series Thermal Shock Test Chamber is suitable for a wide range of applications, including:

- Electronic products: The chamber can test the ability of electronic components and devices to withstand extreme temperature changes, ensuring their reliability and durability.

- Aerospace industry: The chamber can simulate the extreme temperature conditions that aerospace components and equipment may encounter during space missions, ensuring their performance and safety.

- Automotive industry: The chamber can test the ability of automotive parts and systems to withstand sudden temperature changes, ensuring their quality and safety on the road.

- Defense industry: The chamber can test the performance of defense equipment and weapons under extreme temperature conditions, ensuring their reliability and functionality in the field.

Product Advantages:

- Precise and stable temperature control

- Efficient and fast heating and cooling rates

- Large chamber volume size to accommodate various test samples

- Easy to operate with programmable control system

- High-quality materials and advanced technology for long-lasting performance

- Compliant with CE and ISO standards

- Customizable options available to meet specific testing requirements

Conclusion:

The INFINITY IE31 Series Thermal Shock Test Chamber is a reliable and efficient testing equipment that is essential for various industries to ensure the quality and reliability of their products. With its advanced features and customizable options, it is the ideal choice for conducting thermal shock tests in a controlled and precise manner.

Customization:

Brand Name: INFINITY

Model Number: IE31 Series

Place of Origin: MADE IN CHINA

Certification: CE ISO

Our thermal shock test chamber, known as the IE31 Series, is a top-of-the-line product that is designed to meet the highest industry standards. With our advanced technology and commitment to quality, we are proud to offer a wide range of customized services to meet the specific needs of our customers.

Minimum Order Quantity: 1

At INFINITY, we understand that every customer has unique requirements and we are dedicated to providing personalized solutions for each and every one of them. That's why we have no minimum order quantity for our thermal shock test chamber, allowing our customers to order exactly what they need.

Price: Negotiate

We believe in fair pricing and strive to provide the best value for our customers. Our pricing is always negotiable, ensuring that our customers get the most cost-effective solution for their specific testing needs.

Packaging Details: Clear sheet+sponge+wood carton

We take great care in packaging and shipping our products to ensure they arrive in perfect condition. Our thermal shock test chamber is packaged with clear sheet, sponge, and wood carton for maximum protection during transit.

Delivery Time: 20-30 days after order confirmed

With our efficient production process and dedicated team, we are able to deliver our thermal shock test chamber within 20-30 days after receiving the order confirmation.

Payment Terms: TT PAYPAL Moneygram and so on

We offer a variety of payment options to make the purchasing process convenient for our customers. We accept TT, PayPal, Moneygram, and other forms of payment.

Supply Ability: 200 sets / month

Our advanced manufacturing capabilities allow us to produce up to 200 sets of our thermal shock test chamber every month. This ensures that we can meet the demands of our customers in a timely manner.

Temperature Recovery Time: Within 5 Mins

Our thermal shock test chamber is equipped with advanced technology that allows for quick and efficient temperature recovery within just 5 minutes. This feature ensures accurate and consistent testing results.

Inner Material: SUS304# Stainless Steel Plate

We use high-quality SUS304# stainless steel plate as the inner material for our thermal shock test chamber. This ensures durability and resistance to corrosion, making it suitable for long-term use.

Safety Protection Device:

- Heater Anti-burning Protection

- Heater Over Current Protection

- Circulating Fan Over Current Overload Protection

- Compressor High Pressure Protection

- Compressor Overheat Protection

- Compressor Over Current Protection

- Over Voltage Under Inverse-phase Protection

- Circuit Breaker

- Leakage Protection

Safety is our top priority, which is why our thermal shock test chamber is equipped with multiple safety protection devices. These features ensure the safe operation of the chamber and protect against any potential hazards.

Coolants: Non-fluorine Environmental Refrigerant R404A R23 Conforms To Environmental Regulations And Is Safe And Non-toxic

Our thermal shock test chamber uses non-fluorine environmental refrigerants R404A and R23, which comply with environmental regulations and are safe and non-toxic. This makes our chamber a sustainable and eco-friendly solution for temperature testing.

Test Temperature Range: -40°C~+150°C

Our thermal shock test chamber offers a wide temperature range from -40°C to +150°C, making it suitable for a variety of testing applications. This range allows our customers to simulate extreme temperature conditions and ensure the reliability of their products.

Programmable Rapid Temperature Change Test Chamber, Programmable Hot Cold Shock Test Chamber, Programmable Hot Cold Shock Test Chamber For Automotive Electronics

Our thermal shock test chamber is programmable, allowing for rapid temperature changes and precise control over the testing process. This makes it the ideal choice for automotive electronics, where temperature fluctuations can greatly impact the performance of the product.

Packing and Shipping:

Packaging and Shipping

Our thermal shock test chamber is carefully packaged to ensure safe delivery to our customers. Each unit is securely placed in a sturdy wooden crate and padded with foam to prevent any damage during transit.

For international shipping, we use reliable and reputable freight companies to ensure timely and secure delivery. Our thermal shock test chamber is shipped via air or sea, depending on the customer's preference and location.

Upon arrival, our customers can expect their thermal shock test chamber to be well-protected and ready for installation and use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!