Product Description:

Product Overview

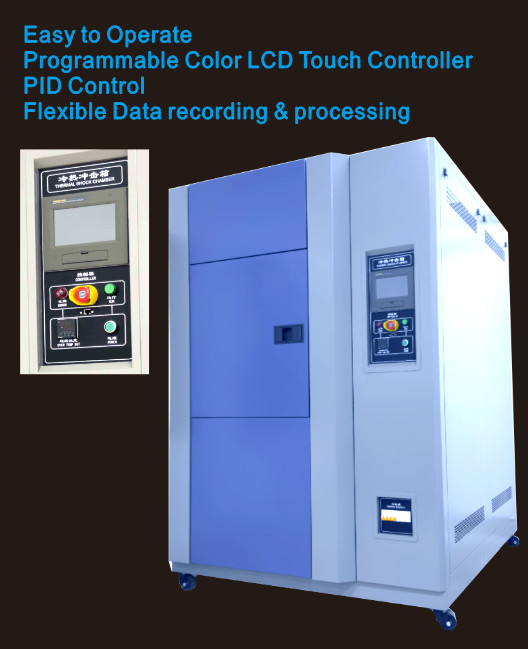

The Programmable Thermal Cycling Shock Test Chamber is a high-precision testing equipment designed for evaluating the performance of materials and products under extreme temperature changes. It is widely used in various industries such as aerospace, automotive, electronics, and telecommunications.

Refrigeration Compressor

The chamber is equipped with a high-quality refrigeration compressor to ensure efficient and stable cooling performance. For the IE31 80L model, a fully closed compressor from France Tecumseh is used, while the IE31A 100L-408L model uses a semi-compact compressor from German Bitzer. Both compressors are known for their reliability and durability, ensuring the longevity of the chamber.

Temperature Recovery Time

The chamber is designed to have a fast temperature recovery time of within 5 minutes, allowing for quick and efficient testing of materials and products. This feature is especially useful for industries with time-sensitive production and quality control processes.

Condenser System

The IE31 80L model is equipped with an air-cooled condenser system, while the IE31A 100L-408L model uses a water-cooled condenser system. Both systems are designed to provide efficient cooling and heat dissipation, ensuring stable and precise temperature control within the chamber.

Temperature Fluctuation

The chamber has a temperature fluctuation of only ±1℃, making it an ideal testing equipment for evaluating the performance of materials and products under extreme temperature changes. This feature ensures accurate and reliable test results, crucial for industries with strict quality control standards.

Chamber Door

The chamber is equipped with a single door, which is specially designed to prevent condensation in the door frame at low temperatures. A heating wire is installed in the door frame, ensuring a dry and condensation-free environment inside the chamber, maintaining the integrity and accuracy of the test results.

Key Features:

- Programmable Thermal Cycling Shock Test Chamber

- Programmable Rapid Temperature Change Test Chamber

- Programmable Thermal Cycling Shock Test Chamber

- High-Quality Refrigeration Compressor

- Fast Temperature Recovery Time

- Efficient Condenser System

- Precise Temperature Control

- Low Temperature Fluctuation

- Specially Designed Chamber Door

Applications:

INFINITY IE31A Series Programmable Thermal Shock Test Chamber

INFINITY IE31A Series Programmable Thermal Shock Test Chamber is an advanced testing equipment specially designed for testing the effects of sudden temperature changes on various materials and products. It is widely used in industries such as electronics, aerospace, automotive, and military for quality control and product development.

Application Scenarios

The thermal shock test chamber is suitable for testing the performance and reliability of electronic components, materials, and finished products under extreme temperature conditions. It can simulate the harsh environmental conditions that products may encounter during storage, transportation, and use, and evaluate their resistance to thermal stress and thermal shock.

Some specific application scenarios include:

- Testing the effects of sudden temperature changes on electronic components such as semiconductors, capacitors, resistors, and PCBs.

- Evaluating the resistance of military equipment to extreme temperature conditions.

- Assessing the performance and reliability of automotive components and materials under extreme temperature conditions.

- Testing the durability of consumer electronics and household appliances in extreme temperature environments.

- Evaluating the resistance of aerospace equipment and materials to thermal stress and thermal shock.

Product Attributes

Brand Name: INFINITY

Model Number: IE31A Series

Place of Origin: MADE IN CHINA

Certification: CE, ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT, PAYPAL, Moneygram, and so on

Supply Ability: 200 sets / month

Insulation material: Hard Polyurethane Foam Insulation Layer + Glass Fiber

Test Standards:

- GB/T2423.1-2001 Low Temperature Test Method

- GB/T2423.2 - 2001 GB/T2423.22-1989 Temperature Change Test

- National Military Standard GJB150.3-86

- National Military Standard GJB150.4-86

- National Military Standard GJB150.5-86

- GJB150.5-86 Temperature Shock Test

- GJB360.7-87 Temperature Impact Test

- GJB367.2-87405 Temperature Impact Test

- J/T10187-91Y73 Series Temperature Change Test Box - Three Box Type

- Meet The Standard IEC68-2-14_ Test Method N_ Temperature Change

Product Name

Programmable Thermal Shock Test Chamber

Product Features

- Programmable rapid temperature change: The test chamber can quickly change the temperature from high to low or vice versa, simulating the sudden temperature changes products may experience in real-world scenarios.

- High-quality construction: The outer material of the chamber is made of high-quality carbon steel plate and undergoes electrostatic color spray treatment, making it durable and resistant to corrosion.

- Programmable temperature control: The chamber allows users to set and control the temperature and time of each test cycle, providing precise and accurate test results.

- Adjustable sample holder: The stainless steel sample rack can be adjusted to two layers and can bear weight up to 30kg per layer, making it suitable for testing different sizes and types of samples.

- Easy operation: The chamber is equipped with a user-friendly interface and control system, making it easy to operate and monitor the testing process.

- Reliable performance: The chamber meets various international and national test standards, ensuring reliable and accurate test results.

Ordering Information

To order the INFINITY IE31A Series Programmable Thermal Shock Test Chamber, please provide the following information:

- Model number: IE31A Series

- Quantity

- Voltage and frequency

- Preferred delivery date

- Optional accessories

For any inquiries or questions, please feel free to contact us. We will provide you with the best solution and competitive pricing.

Get your hands on the most advanced Programmable Thermal Shock Chamber from INFINITY and ensure the quality and reliability of your products!

Customization:

Thermal Shock Test Chamber - INFINITY IE31A Series

Brand Name: INFINITY

Model Number: IE31A Series

Place of Origin: MADE IN CHINA

Certification: CE, ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT, PAYPAL, Moneygram and so on

Supply Ability: 200 sets / month

Key Features:

- Programmable Alternating Thermal Shock Chamber

- Programmable Thermal Cycling Shock Test Chamber

- Programmable Rapid Temperature Change Test Chamber

- Safety protection device: Heater Anti-burning Protection; Heater Over Current Protection; Circulating Fan Over Current Overload Protection; Compressor High Pressure Protection; Compressor Overheat Protection; Compressor Over Current Protection; Over Voltage Under Inverse-phase Protection; Circuit Breaker; Leakage Protection.

- Temperature fluctuation: ±1℃

- Test Chamber Size: 80L/150L/225L/408L

- Temperature Deviation: Less Than 2 Centigrade

- Test Temperature Range: -55°C~+150°C

Packing and Shipping:

Thermal Shock Test Chamber Packaging and Shipping

Our thermal shock test chambers are carefully packaged and shipped to ensure safe arrival and protection of the equipment.

Packaging

The thermal shock test chamber will be packaged in a sturdy wooden crate to provide maximum protection during shipping. The crate will be lined with foam and other protective materials to prevent any damage to the chamber during transit.

Shipping

We offer both domestic and international shipping options for our thermal shock test chambers. Our experienced logistics team will handle all aspects of the shipping process to ensure timely delivery and proper handling of the equipment.

For domestic orders, we offer standard ground shipping or expedited shipping options depending on your needs. For international orders, we work with trusted shipping partners to ensure smooth customs clearance and delivery to your desired location.

Once your thermal shock test chamber has been shipped, we will provide you with a tracking number so you can monitor its progress and estimated delivery date.

We take great care in packaging and shipping our thermal shock test chambers to ensure that they arrive in perfect condition, ready for use in your testing processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!