Product Description:

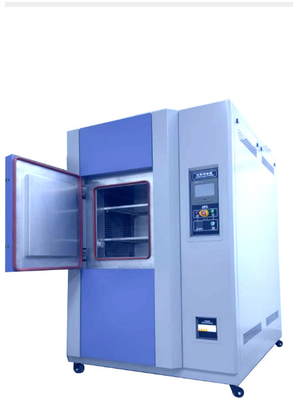

Product Overview - Programmable Thermal Shock Test Chamber

The Programmable Thermal Shock Test Chamber is a highly advanced and versatile testing equipment designed to simulate extreme temperature changes on a product. It is suitable for a variety of industries such as electronic, automotive, aerospace and more. This cutting-edge chamber is built with precision and quality, ensuring accurate and reliable results.

Temperature Deviation

The Programmable Thermal Shock Test Chamber features a temperature deviation of less than 2 Centigrade, providing precise and consistent temperature conditions for testing.

Product Name

The official product name is the Programmable Thermal Shock Test Chamber, also known as a Programmable Temperature Impact Test Chamber or a Programmable Rapid Temperature Change Test Chamber. This versatile machine is designed to meet various testing requirements and is suitable for multiple industries.

Temperature Recovery Time

The chamber has a rapid temperature recovery time of ≤5 minutes, allowing for quick and efficient testing. This feature is especially helpful for industries that require fast and accurate results.

Chamber Door

The Programmable Thermal Shock Test Chamber is equipped with a single door that is specially designed to prevent condensation at low temperatures. It features a heating wire installed in the door frame, ensuring that the door remains free of moisture and ideal for testing.

Models

The chamber is available in five different models, each with varying capacities to meet the specific needs of our customers. The models are IE31A80L, IE31A100L, IE31A150L, IE31A225L, and IE31A408L. Customers can choose the model that best suits their testing requirements.

Key Features

- Programmable Temperature Impact Test Chamber

- Programmable Rapid Temperature Change Test Chamber

- Thermal Shock Chamber

- Temperature Deviation of Less Than 2 Centigrade

- Temperature Recovery Time of ≤5 Minutes

- Single Door with Heating Wire for Condensation Prevention

- Available in Five Different Models

Conclusion

The Programmable Thermal Shock Test Chamber is a highly efficient and reliable testing equipment that can simulate extreme temperature changes on a product. With its advanced technology, precise temperature control, and quick recovery time, it is the ideal choice for industries looking to conduct thorough and accurate tests on their products.

Applications:

INFINITY IE31A Series Thermal Shock Test Chamber

Brand Name: INFINITY

Model Number: IE31A Series

Place of Origin: MADE IN CHINA

Certification: CE ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT PAYPAL Moneygram and so on

Supply Ability: 200 sets / month

Power supply:

- IE31A 80L -100L: AC380V;50Hz;18KW

- IE31A 150L - 225L:AC380;V50Hz;22KW

- IE31A 408L:AC380;V50Hz;25KW

Outer material of the chamber: High Quality Carbon Steel Plate, Surface For Electrostatic Color Spray Treatment. The Left Side Of The Box Is φ50mm Diameter Hole.

Condenser system:

- IE31 80L: Air-cooled

- IE31A 100L-408L: Water-cooled

Temperature Deviation: Less Than 2 Centigrade

Temperature Recovery Time: Within 5 Mins

Product Description:

The INFINITY IE31A Series Thermal Shock Test Chamber is a high-quality and reliable product designed for testing the effects of sudden temperature changes on various materials and products. It is widely used in industries such as electronics, aerospace, automotive, and medical to ensure the quality and reliability of their products in extreme temperature conditions.

Application Scenarios:

The IE31A Series Thermal Shock Test Chamber is suitable for a wide range of applications, such as:

- Electronics: The chamber can test the thermal resistance and stability of electronic components, circuits, and devices under extreme temperature changes. This is essential for ensuring the functionality and durability of electronic products.

- Aerospace: The chamber can simulate the extreme temperature changes that aerospace equipment and materials may experience during flights, ensuring their reliability and safety.

- Automotive: The chamber can test the effects of sudden temperature changes on automotive components, ensuring their performance and durability in different weather conditions.

- Medical: The chamber can test the effects of temperature changes on medical equipment and materials, ensuring their effectiveness and safety for patients.

Features:

- Programmable Humidity Thermal Shock Test Chamber: The chamber can simulate both temperature and humidity changes, providing a more comprehensive testing environment.

- Programmable Rapid Temperature Change Test Chamber: The chamber has the ability to quickly and accurately change the temperature, making it suitable for testing time-sensitive products.

- High-Quality Construction: The chamber is made of high-quality carbon steel plate with an electrostatic color spray treatment, making it durable and resistant to corrosion.

- Easy to Use: The chamber is equipped with a user-friendly control panel, allowing for easy programming and monitoring of the testing process.

- Precise Temperature Control: The chamber has a temperature deviation of less than 2 degrees Celsius, ensuring accurate and reliable testing results.

- Efficient Temperature Recovery: The chamber has a temperature recovery time of within 5 minutes, allowing for continuous testing without long waiting times.

Overall, the INFINITY IE31A Series Thermal Shock Test Chamber is a valuable tool for any industry that requires testing in extreme temperature conditions. Its high-quality construction, precise temperature control, and efficient testing capabilities make it a reliable and essential product for ensuring the quality and reliability of various materials and products.

Customization:

Programmable Thermal Cycling Shock Test Chamber - IE31A Series

Brand Name: INFINITY

Model Number: IE31A Series

Place of Origin: MADE IN CHINA

Certification: CE ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT PAYPAL Moneygram and so on

Supply Ability: 200 sets / month

Product Description

The IE31A Series Thermal Shock Test Chamber is designed and manufactured by INFINITY in China. This programmable high-low temperature shock test chamber is certified with CE and ISO, ensuring its quality and reliability. With a minimum order quantity of 1, the price can be negotiated according to the customer's specific needs.

The chamber door is equipped with a heating wire in the door frame to prevent condensation at low temperatures, ensuring accurate test results. The test temperature range is -55°C~+150°C, with a temperature deviation of less than 2 Centigrade.

Models Available

- IE31A80L

- IE31A100L

- IE31A150L

- IE31A225L

- IE31A408L

Customized Service

INFINITY offers customized services for the IE31A Series Thermal Shock Test Chamber. Customers can choose from different models according to their testing needs. The chamber can also be designed to meet specific requirements, such as different temperature ranges and sizes.

With a supply ability of 200 sets per month, INFINITY can ensure timely delivery of the customized thermal shock test chamber. The packaging is carefully designed to protect the chamber during transportation, using clear sheets, sponges, and wood cartons.

Contact us now to discuss your requirements and get a quote for our high-quality programmable thermal cycling shock test chamber - IE31A Series.

Packing and Shipping:

Packaging and Shipping

The thermal shock test chamber is carefully packaged to ensure safe delivery to our customers. Each unit is first wrapped in protective foam and then placed in a sturdy cardboard box. This helps to prevent any damage during transportation.

We offer both air and sea shipping options for our customers, depending on their location and preference. Our team works closely with trusted shipping companies to ensure timely and secure delivery of our products.

For international orders, we take extra precautions to comply with all customs regulations and ensure hassle-free delivery. Our products are also labeled and marked with handling instructions for safe handling during transit.

Upon receiving the thermal shock test chamber, customers can expect it to be in excellent condition, ready for use.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!