Product Description:

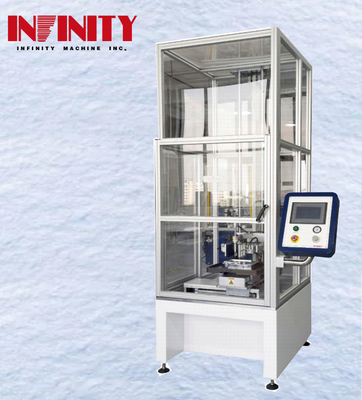

The Three-axis Automatic Drop Ball Machine has a dimension of 1140×1200×2700mm, making it suitable for use in laboratories and manufacturing plants. The machine comes with steel ball specifications of 20g, 500g, or as specified to accommodate different testing requirements.

The Three-axis Automatic Drop Ball Machine has a plant capacity of 1200W, ensuring that the machine can handle a wide range of materials and testing applications. The machine has a height error of ±1mm, ensuring that accurate measurements are obtained during the testing process.

The Y-axis itinerary of the Three-axis Automatic Drop Ball Machine is 300mm, providing ample space for accommodating various testing samples. The machine's three-axis design ensures that the impact is applied uniformly, providing reliable and accurate test results.

Overall, the Drop Ball-impact Tester, also known as the Three-axis Automatic Drop Ball Machine, is an essential equipment for testing the impact resistance of materials. Its compact size, steel ball specifications, high plant capacity, and three-axis design make it an ideal choice for laboratories and manufacturing plants.

Features:

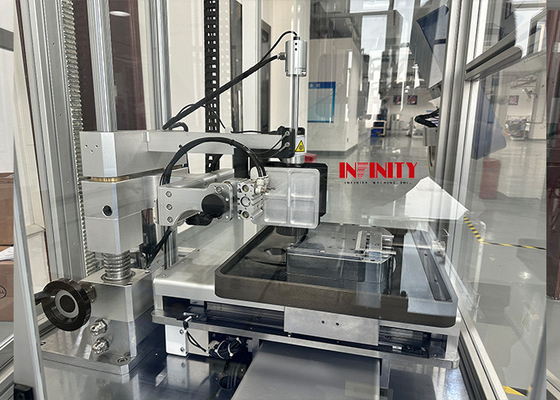

1.The equipment uses vacuum adsorption method to absorb steel balls, which is more accurate than the mechanical claw drop method. At the same time, with the integrated high-speed X-Y platform, it can be programmed to realize automatic multi-point cycle test and improve the test efficiency.

1.The equipment uses vacuum adsorption method to absorb steel balls, which is more accurate than the mechanical claw drop method. At the same time, with the integrated high-speed X-Y platform, it can be programmed to realize automatic multi-point cycle test and improve the test efficiency.

2.X, Y and Z axis are driven by Japan Panasonic servo motor, precision ball screw drive, low noise and durable use.

2.X, Y and Z axis are driven by Japan Panasonic servo motor, precision ball screw drive, low noise and durable use.

3.Language has simplified / English interface, suitable for global customers.

3.Language has simplified / English interface, suitable for global customers.

4.Software operation interface is simple and easy to operate. The program has a designed anti-stay function to ensure the accuracy and safety of each test.

4.Software operation interface is simple and easy to operate. The program has a designed anti-stay function to ensure the accuracy and safety of each test.

5.Unique automatic reset and automatic pickup function, can realize unattended and automatic cycle test. According to the conventional test setting parameters, the steel ball impacts on the sample during starting and running, and the steel ball springs and is clamped by the splint to prevent secondary impact on the sample. When the XY platform is positioned at the position of the cone hole and the ball coaxis, the cylinder is released and drops the steel ball, and the steel ball is automatically reset to the center of the cone hole. After the Z axis drops the ball, the cycle is executed.

5.Unique automatic reset and automatic pickup function, can realize unattended and automatic cycle test. According to the conventional test setting parameters, the steel ball impacts on the sample during starting and running, and the steel ball springs and is clamped by the splint to prevent secondary impact on the sample. When the XY platform is positioned at the position of the cone hole and the ball coaxis, the cylinder is released and drops the steel ball, and the steel ball is automatically reset to the center of the cone hole. After the Z axis drops the ball, the cycle is executed.

6.The whole machine adopts floor structure design, the operation panel can rotate, so that the operator closer to the test area, more convenient sample loading and unloading.

6.The whole machine adopts floor structure design, the operation panel can rotate, so that the operator closer to the test area, more convenient sample loading and unloading.

7.The equipment provides the perfect fault detection mechanism of the operation state, and provides the corresponding error information prompt, and conducts real-time detection and processing of servo failure, sensor fault, X, Y and Z axis limit fault, so as to maximize the protection of personal and equipment safety.

7.The equipment provides the perfect fault detection mechanism of the operation state, and provides the corresponding error information prompt, and conducts real-time detection and processing of servo failure, sensor fault, X, Y and Z axis limit fault, so as to maximize the protection of personal and equipment safety.

8.The device is equipped with infrared laser function, which can accurately locate the position of the landing point and facilitate the tester to accurately determine the test position.

8.The device is equipped with infrared laser function, which can accurately locate the position of the landing point and facilitate the tester to accurately determine the test position.

9.The test formula is stored in the ROM of the system, which is simple and convenient to read and change the test position.

9.The test formula is stored in the ROM of the system, which is simple and convenient to read and change the test position.

Device control interface:

Technical Parameters:

| Product Name |

Three-axis Automatic Drop Ball-impact Test Machine |

| Features |

The Equipment Uses Vacuum Adsorption Method To Absorb Steel Balls, Which Is More Accurate Than The Mechanical Claw Drop Method. At The Same Time, With The Integrated High-speed X-Y Platform, It Can Be Programmed To Realize Automatic Multi-point Cycle Test And Improve The Test Efficiency. X, Y And Z Axis Are Driven By Japan Panasonic Servo Motor, Precision Ball Screw Drive, Low Noise And Durable Use. Language Has Simplified / English Interface, Suitable For Global Customers. Software Operation Interface Is Simple And Easy To Operate. The Program Has A Designed Anti-stay Function To Ensure The Accuracy And Safety Of Each Test. Unique Automatic Reset And Automatic Pickup Function, Can Realize Unattended And Automatic Cycle Test. According To The Conventional Test Setting Parameters, The Steel Ball Impacts On The Sample During Starting And Running, And The Steel Ball Springs And Is Clamped By The Splint To Prevent Secondary Impact On The Sample. When The XY Platform Is Positioned At The Position Of The Cone Hole And The Ball Coaxis, The Cylinder Is Released And Drops The Steel Ball, And The Steel Ball Is Automatically Reset To The Center Of The Cone Hole. After The Z Axis Drops The Ball, The Cycle Is Executed. The Whole Machine Adopts Floor Structure Design, The Operation Panel Can Rotate, So That The Operator Closer To The Test Area, More Convenient Sample Loading And Unloading. The Equipment Provides The Perfect Fault Detection Mechanism Of The Operation State, And Provides The Corresponding Error Information Prompt, And Conducts Real-time Detection And Processing Of Servo Failure, Sensor Fault, X, Y And Z Axis Limit Fault, So As To Maximize The Protection Of Personal And Equipment Safety. The Device Is Equipped With Infrared Laser Function, Which Can Accurately Locate The Position Of The Landing Point And Facilitate The Tester To Accurately Determine The Test Position. The Test Formula Is Stored In The ROM Of The System, Which Is Simple And Convenient To Read And Change The Test Position. |

| Application |

The Machine Adopts PLC Control Mode, The Suction Nozzle Uses Vacuum Negative Pressure, Holding Different Sizes Of Steel Balls, Press The Drop Button, The Suction Nozzle, The Steel Ball Will Be Used As Free Fall Test, Impact The Surface Of The Sample, And Test The Impact Resistance Of The Sample, Which Is Suitable For The Impact Test Of Mobile Phone, Tablet, Audio And Other Electronic Products. |

| X-axis Speed Range |

1~100mm/s |

| Y-axis Speed Range |

1~100mm/s |

| X-axis Itinerary |

420mm |

| Test Height |

50-1200mm |

| Acrylic Ball Specification |

160g Or As Specified |

| Equipment Size |

1140×1200×2700mm |

| Plant Capacity |

1200W |

Applications:

The Impact Testing Machine, also known as the Drop Ball-impact Tester, is a high-quality product manufactured by Infinity Machine. The model number of this machine is ID6150, and it is made in China. This machine is certified by CE and ISO, ensuring its reliability and performance. The minimum order quantity for this machine is 1, and the price is negotiable. The packaging details include clear sheet+sponge+wood carton, and the delivery time is 20-30 days after order confirmed.

The Impact Testing Machine has a supply ability of 200 sets per month, making it a highly efficient and productive machine. The equipment uses a vacuum adsorption method to absorb steel balls, which is more accurate than the mechanical claw drop method. The machine has an integrated high-speed X-Y platform, which can be programmed to realize automatic multi-point cycle test, improving the test efficiency. The X, Y, and Z-axis are driven by Japan Panasonic servo motor, precision ball screw drive, low noise, and durable use.

The language of the machine has a simplified/English interface, making it suitable for global customers. The software operation interface is simple and easy to operate, and the program has a designed anti-stay function to ensure the accuracy and safety of each test. The unique automatic reset and automatic pickup function can realize unattended and automatic cycle test.

The Impact Testing Machine is designed to perform conventional test setting parameters, where the steel ball impacts the sample during starting and running, and the steel ball springs and is clamped by the splint to prevent secondary impact on the sample. When the XY platform is positioned at the position of the cone hole and the ball coaxis, the cylinder is released, and the steel ball is dropped. The steel ball is automatically reset to the center of the cone hole. After the Z-axis drops the ball, the cycle is executed.

The whole machine adopts a floor structure design, and the operation panel can rotate, making it convenient for the operator to load and unload samples. The equipment provides the perfect fault detection mechanism of the operation state, and provides the corresponding error information prompt and conducts real-time detection and processing of servo failure, sensor fault, X, Y, and Z-axis limit fault, maximizing the protection of personal and equipment safety. The device is equipped with an infrared laser function, which can accurately locate the position of the landing point, facilitating the tester to determine the test position.

The test formula is stored in the ROM of the system, which is simple and convenient to read and change the test position. The Acrylic ball specification is 160g or as specified. The Z-axis velocity range is 1-200mm/s, and the X-axis speed range is 1~100mm/s. The working power supply of the machine is AC220V 2A 50Hz.

Customization:

Product Attributes of Infinity Machine ID6150 Three-axis Automatic Drop Ball Machine:

- Brand Name: Infinity Machine

- Model Number: ID6150

- Place of Origin: Made In China

- Certification: CE, ISO

- Minimum Order Quantity: 1

- Price: Negotiate

- Packaging Details: Clear sheet+sponge+wood carton

- Delivery Time: 20-30 days after order confirmed

- Payment Terms: TT PAYPAL Moneygram and so on

- Supply Ability: 200 sets / month

- Acrylic ball specification: 160g Or As Specified

- Y-axis itinerary: 300mm

- Test height: 50-1200mm

- Features: Three-axis Automatic Drop Ball Machine, Drop Ball-impact Tester, Three-axis Automatic Drop Ball Machine

- Application: The Machine Adopts PLC Control Mode, The Suction Nozzle Uses Vacuum Negative Pressure, Holding Different Sizes Of Steel Balls, Press The Drop Button, The Suction Nozzle, The Steel Ball Will Be Used As Free Fall Test, Impact The Surface Of The Sample, And Test The Impact Resistance Of The Sample, Which Is Suitable For The Impact Test Of Mobile Phone, Tablet, Audio And Other Electronic Products.

Support and Services:

The Impact Testing Machine is a sophisticated piece of equipment that requires technical expertise to operate and maintain. Our product technical support and services include:

- Installation and setup assistance

- Calibration and maintenance services

- Troubleshooting and repair guidance

- Software updates and upgrades

- Training and user manuals

We also offer customization services to tailor the Impact Testing Machine to your specific needs. Our team of experienced technicians and engineers are available to provide technical support and services to ensure your equipment operates at peak performance.

Packing and Shipping:

Product Packaging:

The Impact Testing Machine will be packed securely in a wooden crate to ensure safe transportation. The crate will be labeled with the product name and handling instructions.

Shipping:

The shipment of the Impact Testing Machine will be arranged by our logistics team and will be shipped by a reliable carrier. The shipping cost will be included in the price of the product. The estimated delivery time will be communicated to the customer once the shipment is confirmed.

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!