Product Description:

Universal Testing Machine Product Overview

Product Description

The Universal Testing Machine, also known as Material Testing Equipment, is a high precision instrument used to test the mechanical properties of various materials. It is widely used in industries such as metallurgy, construction, aerospace, and research institutions.

Product Attributes

- Test Force Accuracy: ± 1%

- Separate Console and Host: The console and host are separated to ensure a safe distance between the operator and the testing process. The host also has safety protection measures in place for added security.

- Complete Configuration Facilities: The Universal Testing Machine comes with a complete set of configuration facilities, including a force value calibration system and anchor bolts, to ensure accurate and reliable test results.

- Test Speed: 0-100mm / Min

- Product Number: IF7931

- Measurement Range: 12 KN ~ 600 KN Throughout The Whole Process

Product Focus

Tensile Testing: The Universal Testing Machine is specifically designed for tensile testing, which measures the amount of force required to pull a material apart until it breaks. This test is crucial in determining the tensile strength and ultimate tensile strength of a material.

Microcomputer Control Hydraulic Horizontal Tensile Test Machine

The Universal Testing Machine is equipped with a microcomputer control system, allowing for precise and accurate control of the testing process. The hydraulic system provides a stable and uniform force for reliable results. The horizontal design allows for easy loading and unloading of samples.

Tensile Strength Tester

In addition to tensile testing, the Universal Testing Machine can also be used for compression, bending, and shearing tests. This makes it a versatile tool for measuring the strength and performance of different materials.

Conclusion

The Universal Testing Machine is an essential tool for any industry or research institution that deals with materials. With its high precision, complete configuration facilities, and accurate test results, it is the perfect choice for all your material testing needs.

Applications:

Infinity Machine Microcomputer Control Hydraulic Horizontal Tensile Test Machine

Application Scenarios and Usage

The Infinity Machine Microcomputer Control Hydraulic Horizontal Tensile Test Machine, model number IF7931, is a high-quality material testing equipment used for testing the tensile strength and performance of various materials. It is suitable for a wide range of applications in quality control, performance testing, scientific research, education, and industrial production.

The Universal Testing Machine can be used to test the tensile strength of materials such as metals, plastics, rubber, textiles, and composites. It can also be used for testing the tensile strength of finished products, such as screws, bolts, wires, and cables. This versatile equipment can be used in various industries, including automotive, aerospace, construction, and manufacturing.

Product Attributes

- Brand Name: Infinity Machine

- Model Number: IF7931

- Place of Origin: Made In China

- Certification: CE, ISO

- Minimum Order Quantity: 1

- Price: Negotiate

- Packaging Details: Clear sheet+sponge+wood carton

- Delivery Time: 20-30 days after order confirmed

- Payment Terms: TT, PAYPAL, Moneygram, and more

- Supply Ability: 200 sets/month

- Key Technical Indexes: The Console Is Separated From The Host, With A Safe Distance, And The Host Should Have Safety Protection Measures.

- Test Speed: 0-100mm/min

- Measurement Range: 12 KN ~ 600 KN Throughout The Whole Process

Product Features

The Infinity Machine Microcomputer Control Hydraulic Horizontal Tensile Test Machine is equipped with advanced technology and high-quality components to ensure accurate and reliable results. Some of its key features include:

- Control System: The hydraulic test machine special valve controls the loading of the test force, making it easy to operate.

- Measurement System: This machine adopts microcomputer control technology to maintain the load of the test force, ensuring precise and consistent results.

- Display System: The computer screen displays all kinds of test data, draws the test force-time curve, and automates the curve data processing.

- Data Processing: The machine has complete file operation and data storage functions, and the test data is recorded using ASC code, making it convenient for users to process the data.

- Safety Protection: The machine is equipped with a complete safety protection device, including overload protection and travel protection systems. It also has a safety distance between the console and the host for added protection.

Technical Specifications

| Test Speed |

Measurement Range |

| 0-100mm/min |

12 KN ~ 600 KN Throughout The Whole Process |

Product Name

Microcomputer Control Hydraulic Horizontal Tensile Test Machine

For more information about our products, please contact us at sales@infinity-machine.com or visit our website http://www.tester-machine.com .

Customization:

Universal Testing Machine Customized Services

Brand Name: Infinity Machine

Model Number: IF7931

Place of Origin: Made In China

Certification: CE, ISO

Minimum Order Quantity: 1

Price: Negotiate

Packaging Details: Clear sheet+sponge+wood carton

Delivery Time: 20-30 days after order confirmed

Payment Terms: TT, PAYPAL, Moneygram and so on

Supply Ability: 200 sets / month

The console is separated from the host, with a safe distance, and the host should have safety protection measures.

Product Description:

The Universal Testing Machine is a Microcomputer Control Hydraulic Horizontal Tensile Test Machine, designed and manufactured by Infinity Machine in China. This machine is widely used for testing the mechanical properties of various materials, making it an essential tool for quality control in industries such as metal, rubber, plastic, and textile.

Product Features:

- The Configuration Facilities Should Be Complete, Including The Force Value Calibration System, Anchor Bolts, Etc.

- Force measurement mode: Load Sensor Load Measurement

- Maximum test force: 600 KN

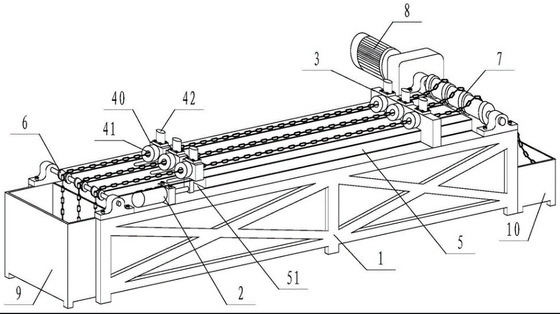

- The Main Engine is mainly composed of cylinder holder, cylinder piston, moving beam, fixed beam and load sensor and other components.

- The cylinder holder, steel plate welding frame, moving beam and fixed beam form the force frame.

- The moving beam and fixing beam are equipped with tensile clamping to hold the two ends of the sample.

- The single out rod low friction piston cylinder drives the moving beam under the action of hydraulic oil, so as to apply the test force to the sample.

- Connect the pin between the fixed beam and the stressed frame to manually adjust the test space.

Product Number: IF7931

Overall Brief:

The Universal Testing Machine consists of a host system and a console. The console is separated from the host, ensuring a safe distance for the operator. The host is equipped with necessary safety protection measures. The host system is mainly composed of a cylinder holder, cylinder piston, moving beam, fixed beam, and load sensor. The cylinder holder, steel plate welding frame, moving beam, and fixed beam form the force frame. The moving beam and fixing beam have tensile clamping to hold the two ends of the sample. The single out rod low friction piston cylinder drives the moving beam under the action of hydraulic oil, applying the test force to the sample. The pin between the fixed beam and the stressed frame can be manually adjusted to change the test space. The configuration facilities should be complete, including the force value calibration system, anchor bolts, and other necessary components.

Keywords:

Microcomputer Control Hydraulic Horizontal Tensile Test Machine, Universal Material Testing Machine, Universal Material Testing Machine Exporters

Packing and Shipping:

Packaging and Shipping for Universal Testing Machine

The Universal Testing Machine will be carefully packaged to ensure safe delivery to our customers. We understand the importance of protecting your investment and want to make sure it arrives at your doorstep in perfect condition.

Packaging:

- The machine will be securely wrapped in protective materials such as bubble wrap and foam to prevent any damage during transportation.

- All delicate parts will be individually wrapped and labeled for easy identification.

- The packaging will be sturdy and durable to withstand any potential mishandling during shipping.

- Instructions for unpacking and setting up the machine will be included.

Shipping:

Our shipping team will carefully handle the package and choose the most reliable shipping method to ensure timely and safe delivery. We offer both domestic and international shipping options to accommodate our customers' needs.

For domestic orders, we offer standard and expedited shipping services. Standard shipping will take 3-5 business days while expedited shipping will take 1-2 business days. International orders will be shipped via air freight and delivery times may vary depending on the destination.

Once the package is shipped, we will provide a tracking number so you can easily monitor the status of your order.

For any questions or concerns regarding packaging and shipping, please don't hesitate to contact us. We want to ensure a smooth and hassle-free delivery experience for our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!